We partner with a major industry in india who manufacture the cloth of any style, any design as per retailers need and manufacture trousers according to their style and specifications.So you choose the cloth and design as per your specification.

|

|

| |

|

|

Our Partner Manufacturing unit is located in India. We are leading manufacturing & exporter, specializing in man-made fabric i.e. suiting shirting and dress material & won the good reputation in quality. The company have installed capacity of 865 nos. High speed imported Sulzer, Airjet picanol weaving machine & 1 CAD/CAM from Wastima Germany, 1200 sewing machine from brother Japan,washing,dyeing & finishing facility in house in the garment division & 3100 rotors for manufacturer of cotton and cotton blended yarn.

Our production volume capacity of manufacturing 90 millions meters man made fabric, 2.5 million pieces of Readymade garment & 10000 mt of yarn per annum. The company have the aim and management guideline Credit-Standing first and customer first, Quality on competitive price available to consumer. Our product enjoy good market inland and also selling well to many countries and areas such as Europe, Africa, Middle East, Srilanka, Thailand. The company is an ISO 9001-2000 certified company & one star export house, exploiting new styles of man-made fabric, Garments and yarn to meet the international trends.

|

|

|

|

|

|

|

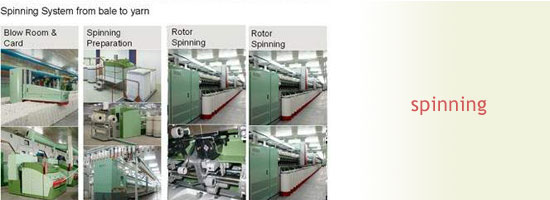

Spinning – Capacity 6200 Rotors – 100% Cotton/Polyester Cotton Blended Yarn 1500 Mt/Month

The Company has latest technology for cotton yarn spinning with a total outlay of 6200 Rotors from world-renowned spinning technology of RIETER equipped with latest quality control equipments combined with computerized information system. The company have universally recognized and accepted high reliability quality control equipments for its Quality Control department to constantly monitor input, in process and output material. Thus impeccable high quality yarn confirming to uster standard is produced.

|

|

|

|

To produce best quality of fabric we have the latest machinery from different parts of the world

|

|

Weaving M/C's:

|

|

Sulzer Ruti PU/P-7100/PS-930 / P7200. |

|

Picanol Airjet/Tsudakoma Airjet. |

|

Warping M/Cs – Hakoba, Westpoint, Prashant Gamatex. |

|

Sizing M/C - Kawamoto, Westpoint, Amritlakshmi. |

|

Jacquard/Dobby- Staubli. |

|

|

The company is equipped with latest weaving technology – Airjet, Rapier and Projectile Weaving machines from Japan, Switzerland combined with preparation Warping and Sizing from Germany and Japan.

|

|

Product

|

Cotton and synthetic fabrics suitable for shirts, trousers, garments and sheeting’s.

|

|

Production Capacity

|

Total 865 High Speed Airjet, Sulzer and Rapier Looms with varied width suitable for single width and double width fabric as well as wider width sheeting’s. Production capacity 7.50 Million mtrs. of fabric per month.

|

|

|

|

|

Our Garments unit having a capacity of manufacturing 2.5 million pieces per annum of garments viz. Trouser, shirts and jeans. The garment unit has been set-up with technical assistance of brother-japan to manufacture for export as well as domestic market.

|

|

Automation

|

|

Automation Spreading and Cutting. |

|

Automation Pattern Sewing Machine For Pocket, Cuffs And Collars. |

|

Automatic Pocket, Cuffs and Collermaking Machine. |

|

Legar And Topper For Finishing. |

|

Washing, Dyeing, Sandblast, Dummy Wash, Ball Wash, Stone Wash, Enzime Wash And Different Washes Facility Available. |

|

|

Plant Area

|

Tonk Unit - 159871 Sq. Yards

Gulabpura Unit - 7562 Sq. Yards

|

|

Equipments

|

Garmets Capacity |

Machine Type |

No. of Machines |

Machine Make |

C. Tonk Unit & Branch Unit Gulabpura |

Cad & Cam |

1 |

Wastema Germany/ Eastern U.S.A. |

|

Computerised Sewing, Cut Pocket, Overlock, Fuesing Machine |

1200 |

Brother Japan |

|

Complete Washing Machine |

20 |

Stefab/ Fabcare India |

|

|

Quality

|

To ensure that high quality levels are achieved in terms of consistency an appropriate selections of machinery has been machines to ensure high level on quality. |

|

Compliance

|

This industry would meet compliance requirements of our needing buyers in terms of safety, adherence to environmental and pollution norms, social obligations etc. And registered under iso 9001. |

|

|

|

|

Our Factories are well equipped with the machineries of latest technology capable of producing World-class quality of fabric.

Woven Fabric – Suiting and Shirting made of Polyester/Viscose, Polyester/Cotton, 100% Polyester and 100% Cotton processing. The Plant among either important machine consist of 8 No.Stenter machines and 2 keise decatvi machine of Biella Italy & TMT Italy, Zero Machine, Lafar Sueding machine Italy.

|

|